call Us

+91 95103 25696

E-mail us

vinod.s@teknikengineers.in

Pipe Supports :

Pipe supports play an important role in the efficient operation of the pipeline. Pipe supports bear the weight and contents of the pipe. To maintain the integrity of the pipeline, the pipeline must be properly supported with appropriate pipeline support. Pipe support engineering is essential to the success of any project as the pipe support must be chosen correctly and judiciously. Pipes with smooth surfaces cannot support themselves, so they must be supported. Pipe Loads are transferred from the pipes to the support structure with the help of pipe supports. Knowledge of proper plumbing support during installation is good.

Pipe support selection is an integral part of piping design. Proper support is essential to avoid vibration, sagging, nozzle damage, excessive stress, etc., in the pipeline. There are a number of typical pipe supports that can be installed to support dead weight loads, and restrain the pipe for thermal and dynamic loads.

Here are some key points about Pipe Supports:

Constant hangers and supports

As the name suggests, there is no change in pipe material due to thermal expansion throughout the range of motion. It is used where large movements are required.

Regular support may be within the specifications of the MSS SP-58 and still have a plus or minus 6% difference over the entire trip.

Variable hangers and Support

In this mode, since the spring is stationary, the load exerted by the bend of the tube changes as the spring moves through its range. This type of support is used for large movements that are not needed.

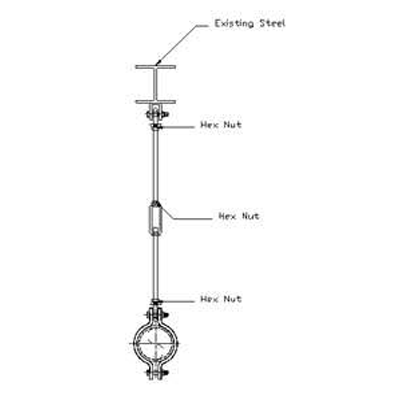

Rigid hangers / Rod hangers

Rigid suspension supports are used to support pipes and limit vertical and lateral movement. Supports for weak pipe include 2 and 3 bolt clamps and riser supports. Binder manufactures brackets in a variety of materials and finishes to suit various load, temperature and environmental requirements.

Snubbers

The use of shock absorbers (snubber) in Critical Pipes is preferred. During a dynamic event, the shock absorber momentarily creates an almost rigid boundary between the guard and the structure. The dynamic energy generated can be instantly absorbed and transmitted painlessly.

The heat transfer during normal operation is not affected by the specific performance of the shock absorber.

Rigid struts

Rigid struts usually consist of steel rods or steel pipes with threaded connections at both ends. One end of the rod is attached to the support member and the other end is attached to the anchor or support. The strut provides a rigid connection between the support member and the fixed surface, limiting the movement of the support member in all directions.

Sway Braces

An Sway braces assembly is a recommended device to control vibration, absorb loads, guide or limit pipe movement due to thermal expansion, and support pipe against sway. They have springs that provide restraint in both tension and compression modes. Sway braces wedges are used to control vibration, absorb shock, guide / guide / limit pipe movement from thermal expansion, and support pipe against swaying.

Sway braces rods are mechanical devices used to provide external support and prevent pipes, pipes and other mechanical devices from moving due to external forces such as wind, earthquakes and other events. It is designed to prevent external forces that could support or wobble the assembly, cause damage, or affect the integrity of the hull.

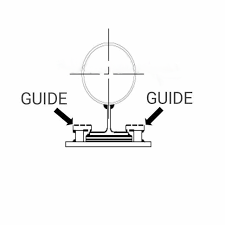

Pipe Guide

Pipe guides are used to allow pipe to move in a predetermined direction while restricting movement in other directions. Like directional pipe anchors, pipe guides are supports that encourage movement in a particular direction. Generally, pipe guide anchors can follow pipe guide. However, the main function of the pipe guide is to push the pipe correctly while adding other protection.

Pipe guides are mechanical devices used to provide external support and guidance for pipes, tubing and other mechanical equipment. It is designed to prevent the movement of supporting objects that could cause damage or affect the integrity of the body.

Limit Stop / Line Stop

This brake is made of stainless steel with stainless steel inside. The function of these buttresses is to prevent excessive stress on the pipeline by restricting movement caused by earthquakes or similar events. A device that allows rotation but prevents pipe displacement. limit stop or line stop against the movement of the pipe in the axial direction of the pipe. This is also called a stopper.

Back abutments or column abutments are not generally used as Pipe Supports. While they are often used to limit the movement of valve stems or actuator shafts, they are not designed to provide the necessary support for piping or other mechanical components.

Anchor

A pipe anchor is a pipe support used to control pipe movement by securing pipe to a central joint. Pipe anchor brackets are essential in plumbing and drainage systems. The exact thermal performance of the pipeline is determined by the location of the pipeline anchor. There is no alternative to pipe anchors to properly control thermal expansion and contraction. In this article, we will try to understand the basics of pipe anchor brackets.

Anchor Pipe Supports are rigid supports used to prevent pipes and other mechanical equipment from moving in a certain direction. They are generally used in applications where there is a risk of thermal expansion or contraction, seismic activity, wind or other external forces that could cause the supporting material to move or change.

Special Pipe Supports

Custom Pipe Supports are designed and manufactured to meet the specific needs and challenges presented by a particular application or installation. These brackets are usually custom made and designed to provide proper support and stability to the supporting material.

These brackets are designed to support the expansion joints used to accommodate the thermal expansion and contraction of the pipe. Integration support will include instructions, restrictions and other tools to ensure the integration works properly.

Shoe Support

Pipe shoes are an important piece of pipe support that prevents damage and extends the life of your piping system. This guide explains how pipe shoes are made, the types of pipe shoes available on the market today, and how to make the most of them.

Shoe support, also known as pipe shoe, is a pipe used to support and protect pipe in areas at risk of damage or wear. Boots are often used in applications where there is a lot of pipe movement or where there is a risk of clogging or damage.

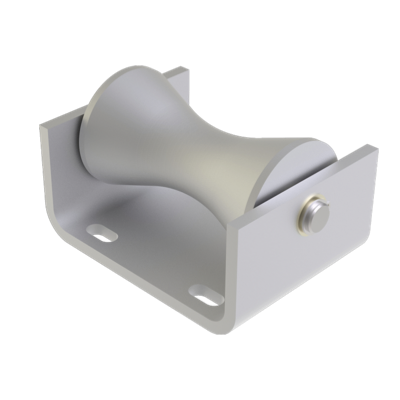

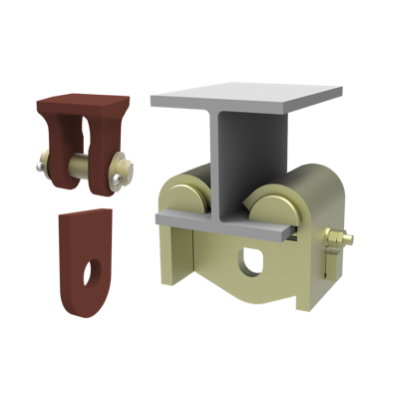

Roller bearing Support

Horizontal piping systems are supported longer by rolling or sliding support beds and anchor points. Support elements are designed as sliding or roller type to allow normal thermal movement.

For large diameter piping systems subjected to high loads, roller bearings are the best solution. They have high bearing capacity, high reliability and low friction.

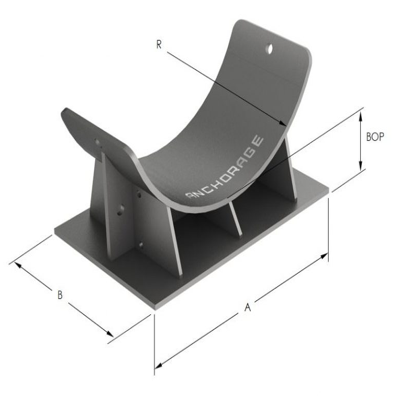

Saddle Support

Horizontal piping systems are supported longer by rolling or sliding support beds and anchor points. Support elements are designed as sliding or roller type to allow normal thermal movement. For large diameter piping systems subjected to high loads, roller bearings are the best solution. They have high bearing capacity, high reliability and low friction.

Roller bearing brackets are a type of pipe bracket designed to provide convenience and support for pipes and other mechanical equipment. Roller bearings are often used in applications where there is a risk of thermal expansion or contraction, and in areas where there is seismic activity or other movement.

Clamp support

Clamp support is a type of pipe support used to provide support and stability to pipes and other mechanical equipment. Clamp support is often used in applications where pipes or equipment need to be fixed or held, such as in stormy or seismic areas.

U-bolt Support

A U-bolt is a U-shaped twisted bolt with threads on both ends, used as a fasten in pipes and water pipes. U-bolts are one of the simplest and most commonly used types of pipe support. They generally work in the form of rest+education+care support; with a little configuration, they can be replaced when the line stops. The curved U-bolts fit snugly around the pipe and are then fixed with nuts and unions.

U-bolt pipe support is a pipe support used to provide stability and support for pipes and other mechanical equipment. U-bolt pipe support is often used in applications where pipe or equipment needs to be fixed or restrained, such as in stormy or seismic areas.

Cardel / Wear Pad

Cradle / Wear Pad Also known as non-metallic wear pads, these materials are used in insulated pipes to prevent corrosion and extend the life of the pipes. They also eliminate metal-to-metal contact and electrically isolate pipes from pipe racks and other metal equipment.

Cardel or Wear Pad Pipe Support is a type of pipe support used to protect and support pipelines and other mechanical equipment. These brackets are often used where there is a need to reduce wear on pipe or equipment, such as in applications where there is significant vibration or movement.

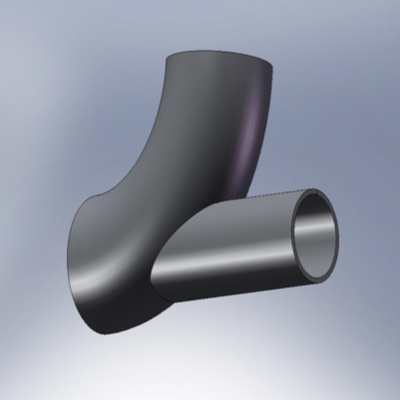

Trunnion / Dummy Support

A trunnion is a length of pipe that you attach to a vertical pipe for extra support. They are usually welded to the area of the pipe that needs to be able to carry more.

The dummy support has a piece of pipe welded to the back of the elbow. It supports your elbow and bridges the point where your pipe changes direction and your nearest point of support.

The trunnion or virtual support pipe is a type of pipe support used to provide stability and support to pipes and other mechanical equipment. Trunk brackets are often used in applications where large and heavy pipes or objects need to be supported, such as pipelines or process plants.

Structural attachments

Structural attachments are critical components used in construction and engineering to connect different structural elements together. These elements may include steel beams, columns, plates, and braces, among others. The purpose of these attachments is to transmit loads and stresses between the various structural elements while maintaining their stability and integrity.

The selection of the appropriate attachment depends on various factors, such as the type of structure being built, the materials used, the loads and stresses it will be subjected to, and environmental factors such as temperature and humidity. Proper selection and design of structural attachments are critical to ensuring the safety and longevity of the structure.

Get in touch

You will find yourself working in a truly collaborative environment, resulting in an incredible experience and the best end product.